Precision and Objectivity in Industrial Processes

Spectral-Fluorescence-Signature (SFS) Method

by Senmark Invest OÜ

Qualitative and quantitative determination of single components in complicated mixtures is often a burdensome, time consuming and expensive procedure. Especially in the processes in the food industry, where the quality of the produce depends on the right proportions and maturity rates.

Empirical judgement of the production process based solely on workforce experience may not result in stable and controlled quality of the produce. Using specific quantitative parameters to guide these industrial processes is significantly more precise and objective. A solution for this would be to use the spectral-fluorescence-signature (SFS) method, where the fluorescence of different substances (ie. amino acids, vitamins etc) are precisely measured.

To that effect, the subject mixture is excitatated by intense light spectrum after which the released fluorescence signature is registered and measured. All substances have their own unique signature in the form of different spectral wavelengths in which they can be excitatated therefore this method can determine the desired qualitative and quantitative amounts of individual substances in mixtures.

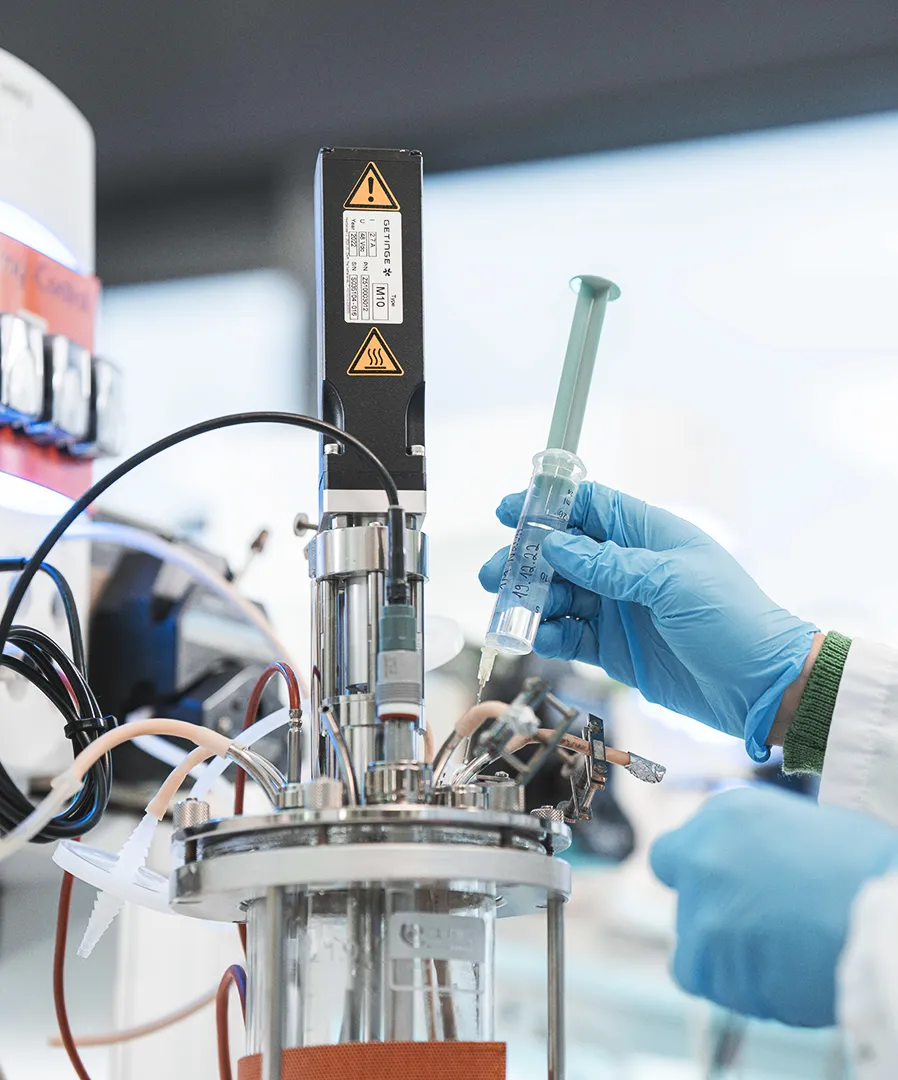

In most cases the equipment for such measurements have been prototypes for lab studies. They are relatively multifunctional and precise, but too fragile and clumsy for industrial use. The need to automate the production processes to ensure even and controlled quality of the end produce have created a need to develop technology suitable for any specific manufacturing conditions.

Senmark Invest OÜ was established in 2014 with the goal to develop these forementioned solutions for different food manufacturers as well as companies making this kind of specialized equipment.

Our company started with research in different kinds of sensors and their application possibilities, however we now focus primarily on applications of fluorescence spectroscopy.

In the research and development process we have cooperated with the leading scientists and laboratories in Estonia as well as specialists and manufacturers in the food industry in Estonia and internationally. We value these long-term partnerships with everyone involved working to ensure the highest quality product.

Our research in this area has also been published in an article in the reputable international science magazine MDPI.

Our goal is to find new solutions and develop different control and management systems for both industrial manufacturing and commercial production needs.

Ongoing research

Development of the Fluorescence spectroscopic measuring system

The goal for this developmental study is to create technology to measure fluorescence in a package that is suitable for industrial use, which would optimize the production processes, measuring the parameters of organic substances in an online principle.

We are currently focusing our testing on the workflow processes of milk and soft drinks manufacturers, but also looking into monitoring waste waters.

As a result, we are able to control the production cycles and their changes as well as optimize the production losses when switching from one product to another. For example, manage the processes of industrial washing systems, including monitoring of the effectiveness of the wash and the residue of the detergents; monitor the quality parameters of the industrial waste waters; monitor and control the coagulation of cheese etc.

This sensor-based technology is being developed along with respective software and will allow monitoring manufacturing in real-time in addition to collecting data of the process flow. The ability to get real-time feedback will enable precise control and optimization over these processes. Initial lab-testing with the prototypes have shown that the technology is indeed suitable for the type of practical application described above.

In order to fully test the capabilities of the sensors, a suitable method of testing was created and proper control-equipment was acquired.

This study is conducted in cooperation with Tehnolabor OÜ and AS TFTAK. Technologies developed during this research will enable manufacturers ensure higher quality product with less cost. The advantages of our system are real-time workflow feedback and multifunctionality – it is designed to solve industry-specific problems. The systems developed and offered by Senmark Invest OÜ are unique and they can be installed in both existing and new manufacturing lines and equipment.

Senmark Invest OÜ

Peterburi tee 46, 11415 Tallinn

Estonia

+372 6201 471

+372 50 45 820

roman.loov@joeston.ee